Supporting the Motor Manufacturing

with Proven Solutions

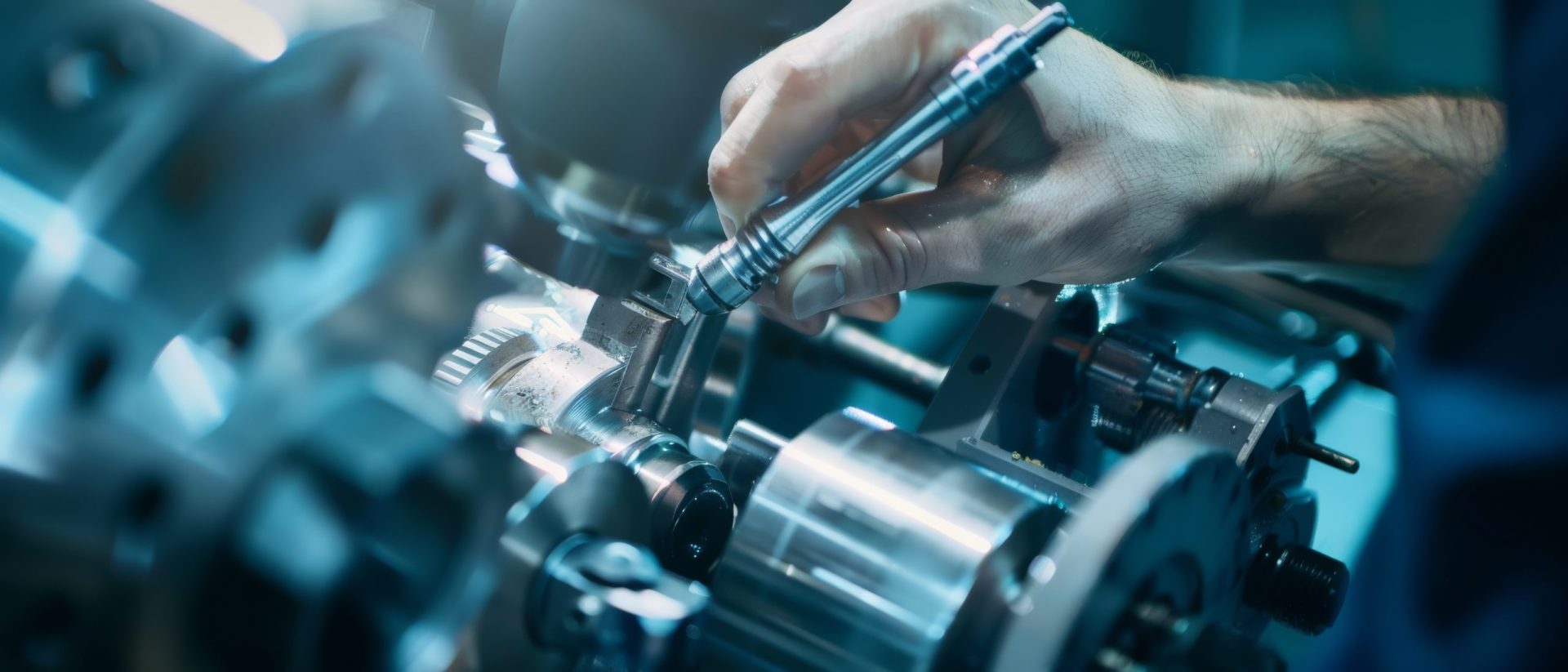

We help manufacturers solve production bottlenecks, supply chain gaps,

and operational inefficiencies with proven strategies and real results.

How We Help Power the

Motor Manufacturing Industry

Our advanced resin systems, industry certifications, and decades of expertise

make us a trusted partner for motor manufacturers worldwide

Manufacturers Served

Global motor manufacturers trust our custom resin solutions

Specialized Products

Tailored materials engineered for electric motor needs.

Years of Expertise

Decades of hands-on experience in motor production support.

UL Certifications

Resin systems tested and approved for compliance.

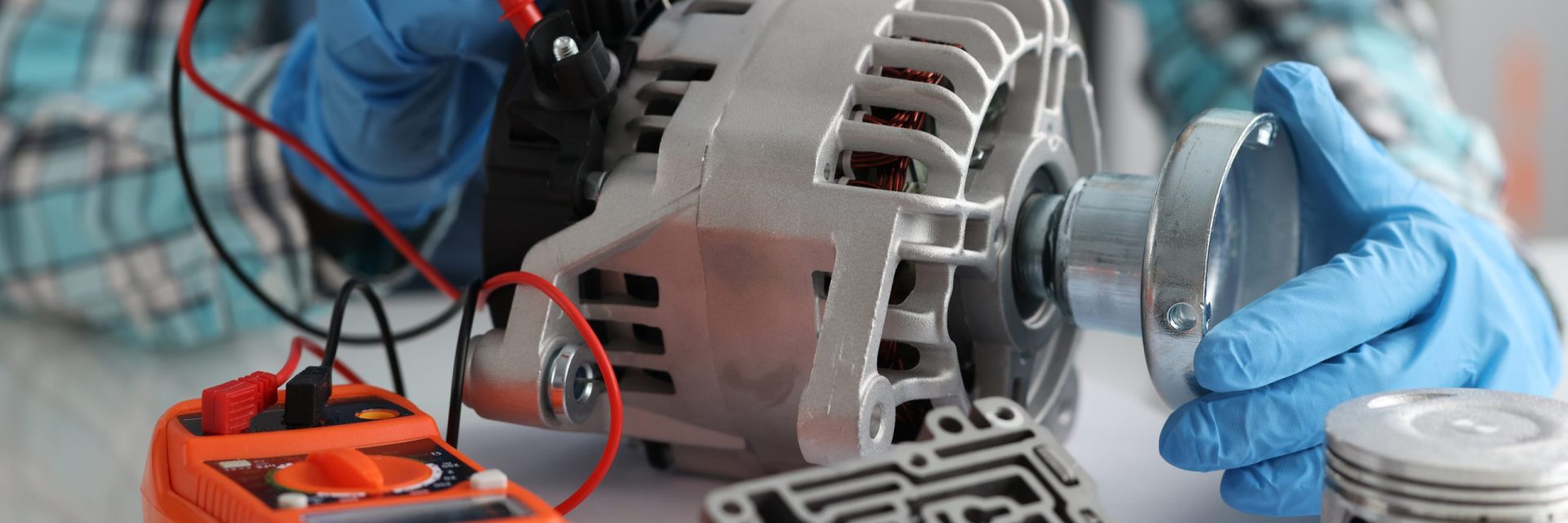

Technical Validation for

Motor Manufacturing Applications

From high-speed winding to thermal insulation and compliance with UL standards.

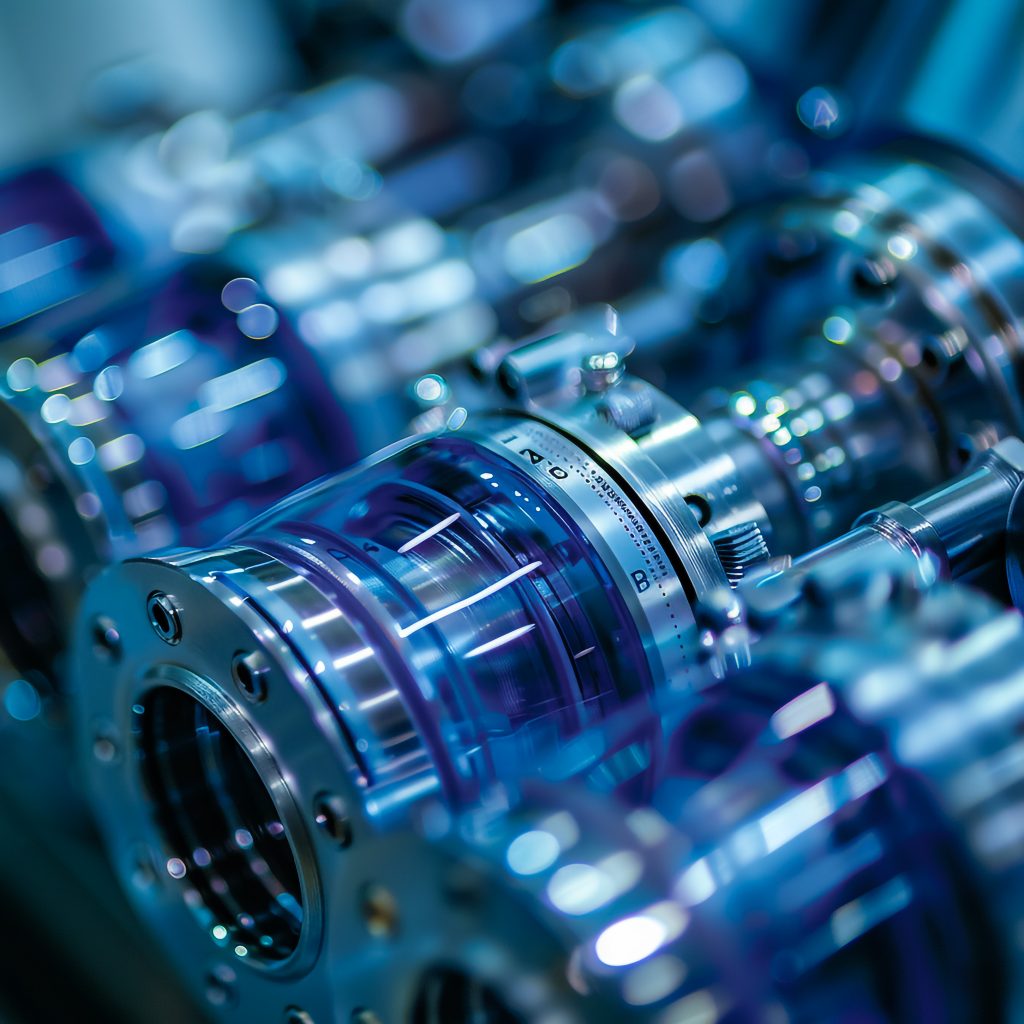

Reliable Resin Systems for High-Speed Winding

Improve thermal stability and vibration resistance in high-RPM environments.

Trusted Insulation for Heat-Intensive Motor Cores

Proven performance in dielectric strength and thermal cycling at 200°C+.

Resin Solutions for Complex Geometries

Flow-optimized systems ideal for small motor housings and precise applications.

Technical Resources

for Motor Engineers

Access downloadable documentation to support material validation, compliance checks, and application planning — all specific to motor manufacturing needs.

Resin Selection for

High-Speed Motors

Resin Selection for

High-Speed Motors

Insights on selecting the right resin for high-RPM motor applications.

Download WhitepaperUL-Certified

Products List

UL-Certified

Products List

Complete list of UL-certified EFI products used in electric motor applications.

View UL Product ListProduct Spec Sheet:

EP-3100 Series

Product Spec Sheet:

EP-3100 Series

Performance specs and for EP-3100, commonly used in stator encapsulation.

Go to Product PageResin Compatibility Chart

Resin Compatibility Chart

Quick reference for selecting the right resin based on thermal, electrical, and size.

Request Resin Chart

Let’s Solve What’s Slowing You Down

Ready to streamline operations or tackle a recurring issue?

Talk to our team about what’s possible in your plant.

Motor Manufacturing FAQ

EFI Polymers offers a range of epoxy, polyurethane, and silicone resin systems designed specifically for motor applications, including potting, encapsulation, insulation, and flame resistance.

Yes. EFI Polymers is ISO 9001:2015 certified and offers multiple UL-listed materials, including UL 1446-certified insulation systems and UL 94-rated flame-resistant resins.

Our team works closely with manufacturers to develop tailored resin formulations that meet specific thermal, dielectric, mechanical, and processing requirements for unique motor designs.

EFI’s resins are engineered for consistent performance, fast processing times, superior thermal stability, and long-term reliability — making them ideal for scaling high-volume production with minimal downtime.

Absolutely. With domestic production facilities and a flexible supply chain, EFI ensures reliable resin availability, inventory planning support, and quick turnaround times to keep motor manufacturing programs on schedule.