Advanced Epoxy & Polyurethanes

for Electrical Potting

We offer advanced potting materials and expert support for high-performance electronics,

ensuring innovation, reliability, and tailored solutions for demanding industrial applications.

Advanced Potting Solutions

for Electronics Protection

High-performance potting systems designed for durability and efficiency.

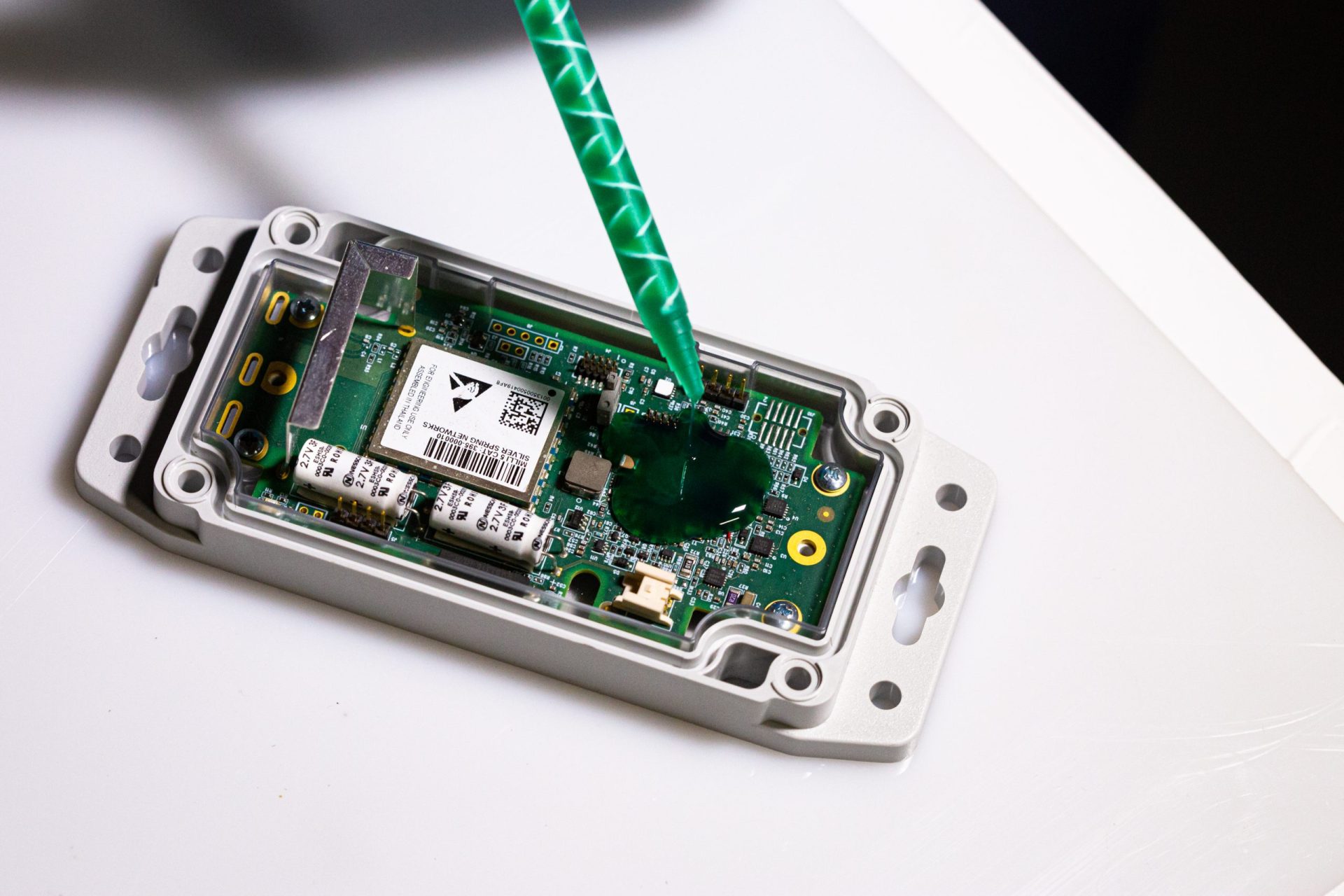

Protect Sensitive Electronics

Protect Sensitive Electronics

Protect Sensitive Electronics with Ultra Low Tg Urethanes for enhanced flexibility and compliance

Reduce Defects

Reduce Defects

Reduce defects improve efficiency with a materials tailored to your part design and manufacturing process

Get Expert Support

Get Expert Support

Get expert support for processing two-component epoxy and urethane materials

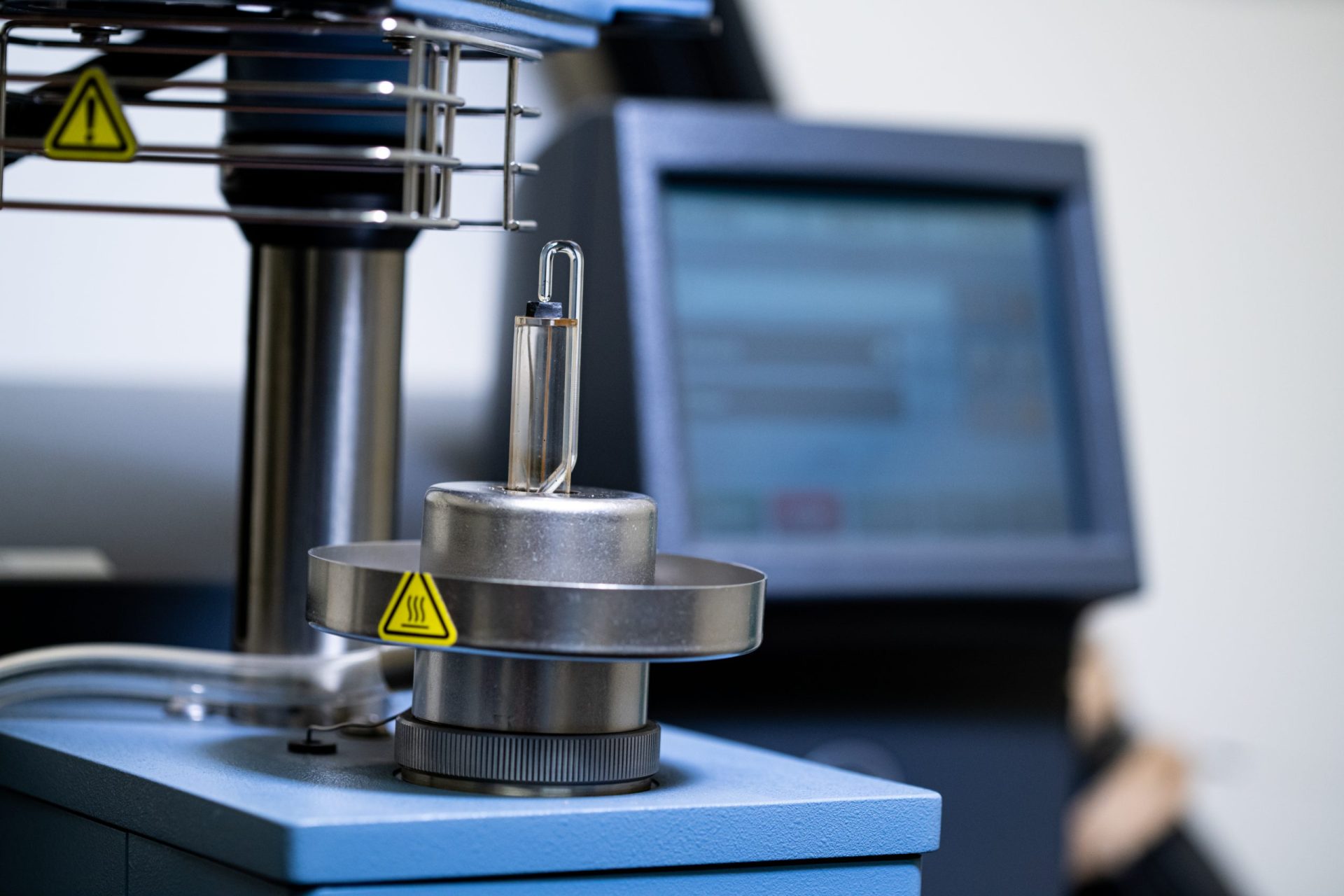

Enhance Heat Dissipation

Enhance Heat Dissipation

Enhance Heat Dissipation with High Thermal Conductivity Epoxy Systems

| System ID | Description | Operating Temp | Hardness | Tg | Gel Time | Mixed Viscosity | CTE |

|---|---|---|---|---|---|---|---|

| 20203&50002 | Epoxy, black, low-cost, low viscosity potting material with good moisture resistance, excellent adhesion and moderate thermal conductivity. | -40 to 150°C | 85 Shore D | 53°C | 160 mins (100g@25°C) | 1,700 cps | 55 µm/m°C |

| 20352&50150 | Epoxy, black, UL 94V0 non-flammable potting material, with good thermal conductivity, excellent adhesion, very good moisture resistance. | -40 to 150°C | 87 Shore D | 100°C | 60 mins (200g@25°C) | 5,000 cps | 40 µm/m°C |

| 20366&50171 | Epoxy, black, UL94V0 non-flammable potting material with very good thermal conductivity, excellent adhesion, and very good moisture resistance. | -40 to 150°C | 85 Shore D | 82°C | 100 mins (100g@50°C) | 3,000 cps (resin @ 50°) | 48 µm/m°C |

| 30048&40049 | Urethane, amber, very low viscosity, soft potting material. Excellent thermal cycling capabilities with sensitive electronics, very good moisture resistance, good adhesion. | -40 to 120°C | 55 Shore A | -7°C | 70 mins (100g@25°C) | 850 cps | 240 µm/m°C |

| 30207&40002 | Urethane, amber, very low viscosity, soft potting material. Excellent thermal cycling capabilities with sensitive electronics, very good moisture resistance, good adhesion. | -40 to 120°C | 90 Shore A | -8°C | 40 mins (200g@25°C) | 3,000 cps (polyol @ 35°C) | 140 µm/m°C |

| 30263&40064 | Urethane, amber, very low viscosity, soft potting material. Excellent thermal cycling capabilities with sensitive electronics, very good moisture resistance, good adhesion. | -70 to 100°C | 65 Shore A | -78°C | 200 mins (100g@25°C) | 3,100 cps | 167 µm/m°C |

Protecting Electronics

Across Industries

EFI Polymers delivers trusted potting solutions for global OEMs and niche manufacturers. Our custom formulations address thermal shock, voids, and cracking—while meeting compliance and production goals. With deep technical expertise, we go beyond the spec sheet.

- Engineered to prevent thermal shock, voids, and cracking

- Proven to meet strict compliance and production standards

- Backed by deep technical expertise and industry partnerships

We Create Custom Formulations

Don’t See What You Need? We tailor solutions to meet your exact needs –

even for the toughest applications.

FAQ

Electrical potting is the process of encapsulating electronic components in a protective material—such as epoxy, urethane, or silicone—to shield them from moisture, dust, vibration, and other environmental hazards.

Potting enhances the durability and reliability of electronic assemblies by preventing short circuits, corrosion, and mechanical damage. It also helps with thermal management and can improve product lifespan.

Common potting materials include epoxies (for high strength and thermal resistance), urethanes (for flexibility and low-temperature performance), and silicones (for high-temperature and moisture resistance).

The best material depends on your application’s requirements—such as operating temperature, exposure to chemicals or moisture, cure time, and mechanical stress. Consulting with a materials expert can help you select the ideal formulation.

Consult with EFI Polymers for a holistic needs analysis of your product and process.

Yes! Many manufacturers, including EFI Polymers, offer custom formulations tailored to specific performance needs, processing methods, and compliance standards.