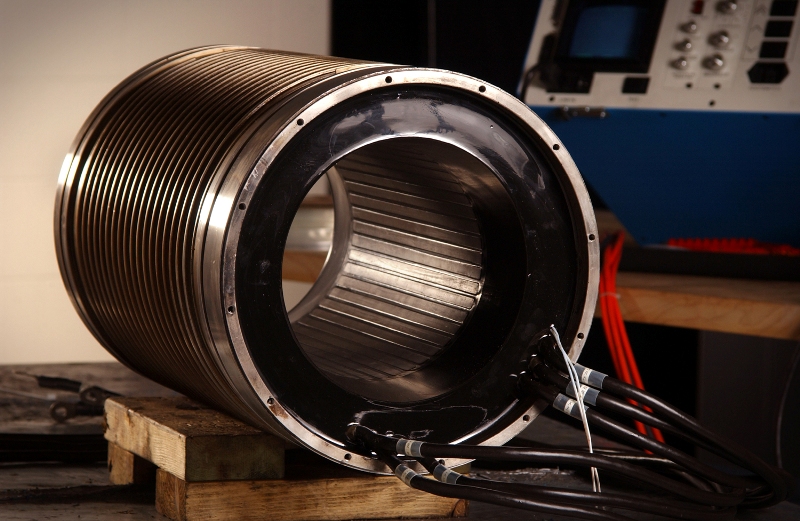

Motor & Stator

Encapsulation Products

EFI has a suite of motor potting epoxies and polyurethanes, and

decades of process experience.

Motor Potting Expertise

Your one-stop shop for motor potting materials and support.

- Low Viscosity for Easy Processing – with mixed viscosity of less than 1000 cps, easily fill your stator without trapping air

- High Tg – for motors that need to operate at high temperatures – choose our elevated Tg materials for thermal stability

- UL 1446 Listed Systems – easily maintain your UL listing by choosing one of our UL 1446 listed Electrical Insulation Systems (EIS).

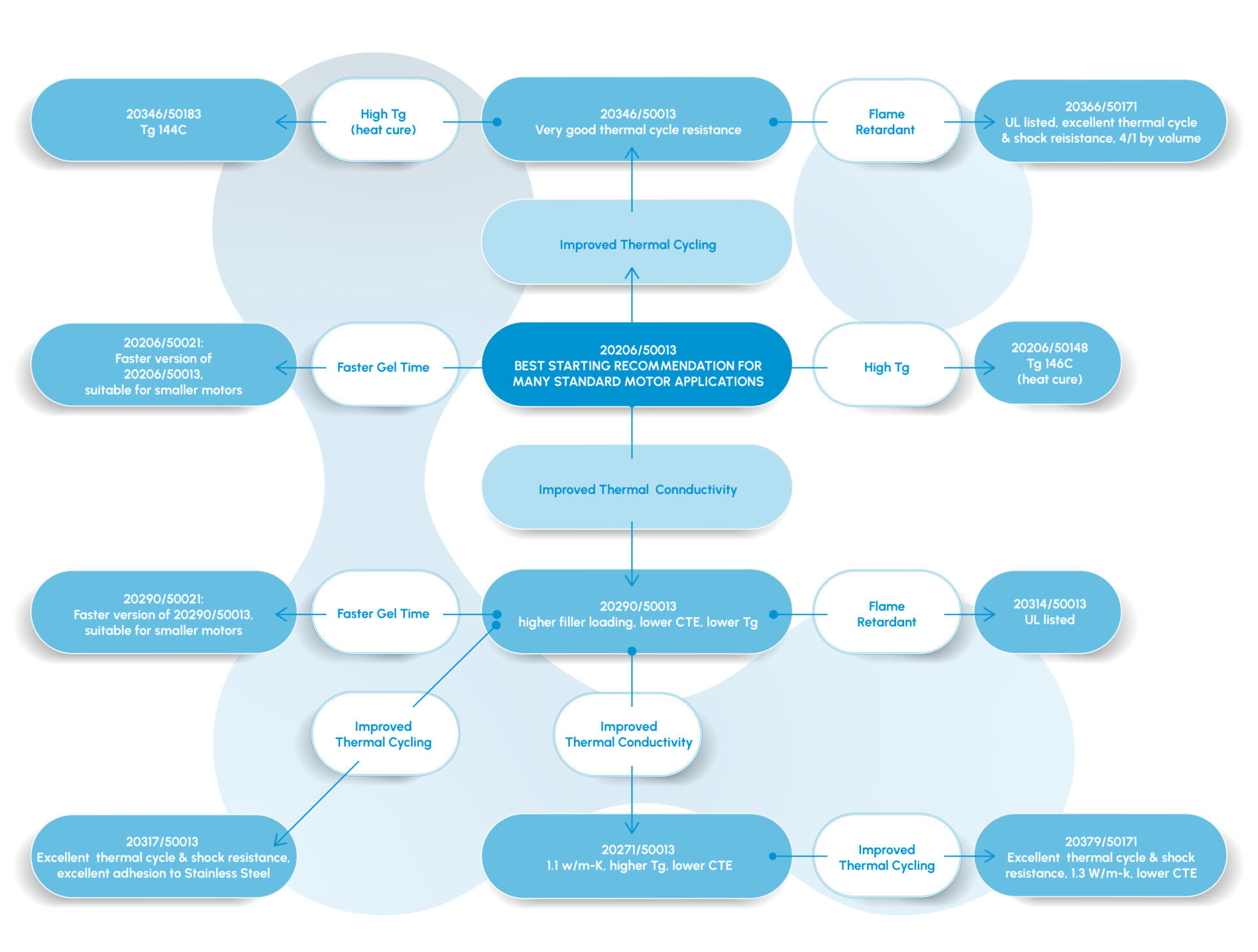

Premium Motor Potting Materials

for all Applications

Proven Motor Potting Expertise

Developed through real-world applications, backed by expert support and responsive service.

- End-to-End Support: From concept to production, we provide expert guidance and responsive service every step of the way.

- Collaborative Product Development: We partner with you to engineer tailored solutions that meet performance, cost, and timeline goals.

- Reliable Supply & Quality: Consistent, high-quality manufacturing backed by a dependable supply chain you can trust.

Your Partner for Motor/Stator Encapsulation

Let us provide expert help in enhancing performance of your motor with motor/stator encapsulation.

FAQ

We have systems ranging all the way to 1.6 w/mk. While we are aware that there are motor potting systems with higher ratings than this, we find that anything above 1.6 is quickly reaching diminishing returns. We have found this to be the high-end sweet spot, where materials can still penetrate windings and deliver efficient thermal transfer.

The two most common reasons include enhancing performance and protection from elements. Many wash-down duty motors are encapsulated to guarantee long-term performance in harsh environments. Many high performance motors are encapsulated to increase the ability of the motor to move heat out of the windings, increasing efficiency and performance.

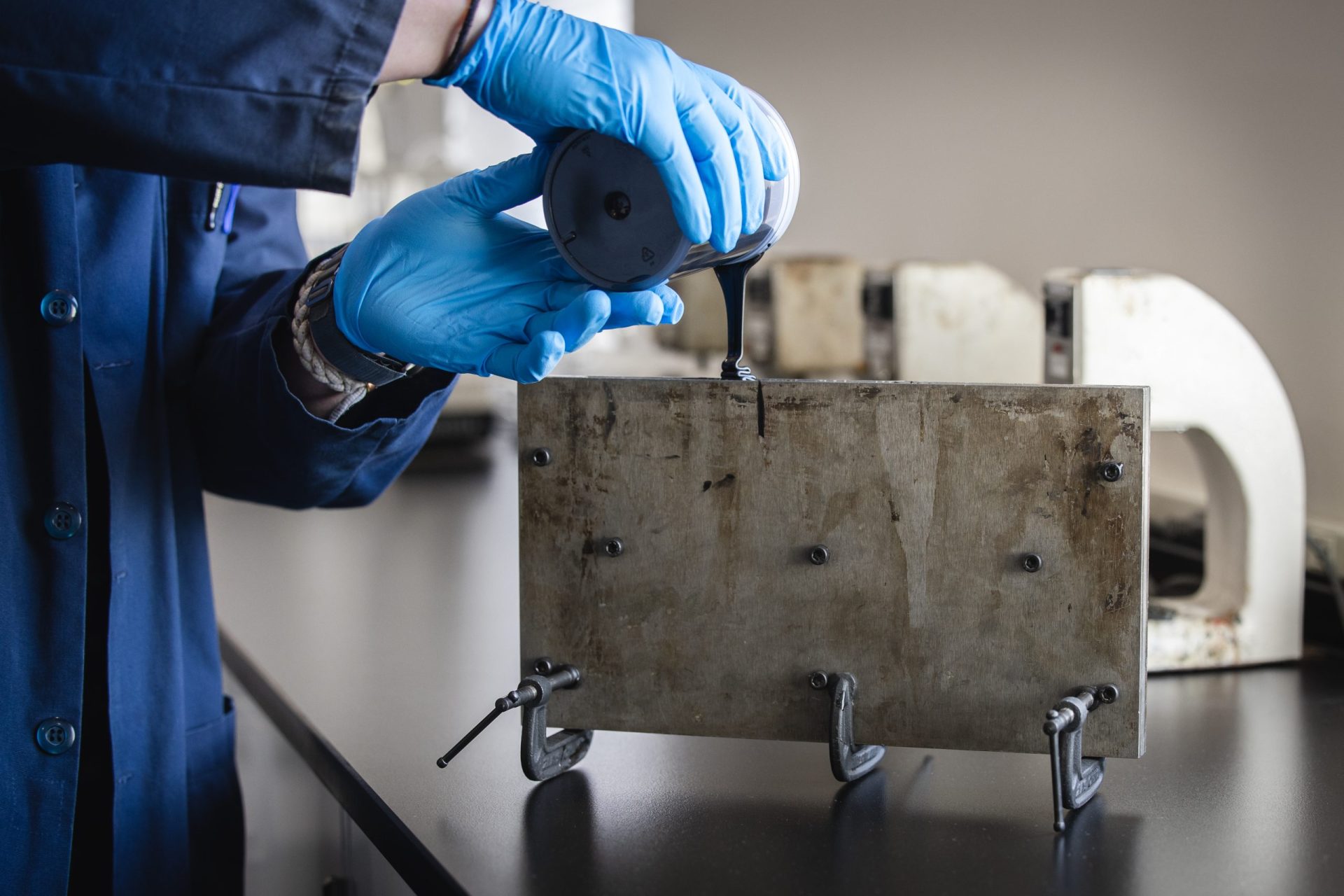

Most of our motor potting systems are low viscosity, especially when preheated. In many cases, the dispensing process will include a vacuum process to ensure a full, airless dispense.

EFI has several ways to help. In the trial phase, it may be possible to test using hand-mixing and vacuum pot. Or EFI can enlist the help of one of our dispense machine partners. When it comes to production, EFI has close partnerships with several meter-mix dispense machines, who we will work closely with to help design your process.